Stone Mining Mill Materials Calculation

.jpg)

Reduction of Fragment Size from Mining to Mineral

2022年10月4日 The effects of rock fragmentation on the whole size reduction chain from mining to mineral processing are described The main factors influencing rock fragmentation by 2024年9月1日 By optimizing underground mine bench blasting practices, mining companies can reduce their environmental footprint, improve operational efficiency, and enhance longterm Integrating Underground Blast Fragmentation Modeling for 2017年8月26日 The objectives of this study are: (a) to investigate how long the limestone quarry can alone supply the desire quality and quantity materials to the cement plant; and (b) to MINERAL MINING TECHNOLOGY Limestone Quarry 2023年12月4日 A slope stability calculation method is proposed based on rigid body‐limit equilibrium theory that can quantify the influence of highwall mining operations on slopeSlope stability calculation method for highwall mining

.jpg)

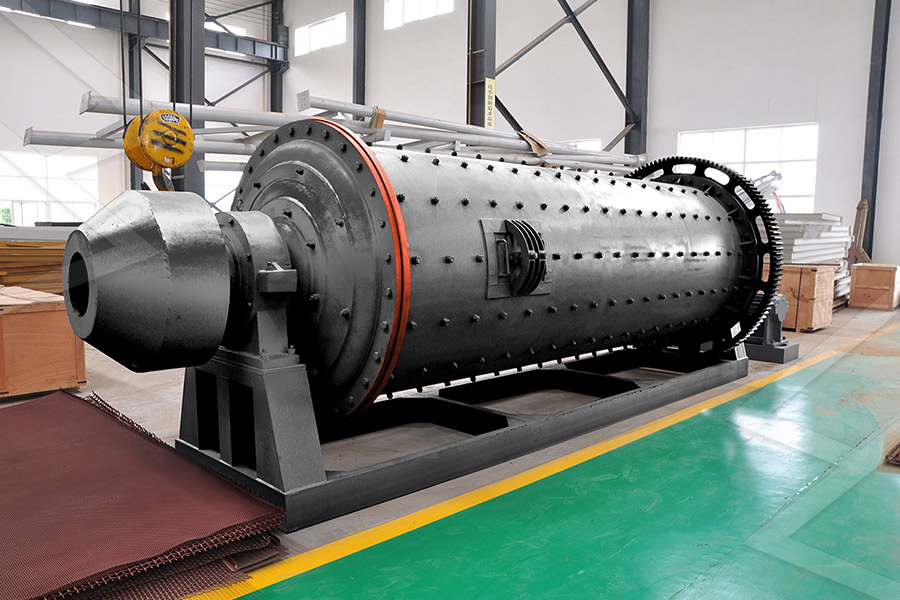

Ball Mill Design/Power Calculation

2015年6月19日 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill 2022年11月6日 The two main goals of this paper are to (a) determine how long an operating mine can continue to provide the cement plant with the quality and quantity of materials it needs, and (b) explore the viability of combining some An Optimized Open Pit Mine Application for Grinding Mills – Sizing Mill Calculations v2a, PDF 443 KB (provided by Brian Povey) Mill Bulk Factors for Expansion of Common Rock Materials, PDF 37 KB (provided by The AusIMM) List of Common Minerals in Reproduced from Minerals Processing Toolbox AusIMM2024年1月9日 Diamond wire saw cutting is a popular dimension stone mining technique around the world Estimation of the production cost for this method is critical for these operations In Cost modelling for dimension stone quarry operations

.jpg)

ball mill calculation for mining machinery – stone cruxder

Comprehending milling calculations is crucial for optimizing ball mills’ performance in mining operations Factors such as mill size, rotational speed, and power requirements all play significant roles in achieving efficient grinding processes that yield desirable outcomes Common Mistakes in Ball Mill Calculations and How to Avoid Them 2015年6月19日 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill Ball Mill Design/Power Calculation2024年9月1日 21 Role of Blast Design in Sustainable Mining and Mineral Processing Utilizing blasting for rock fragmentation offers distinct cost advantages over employing crushing and grinding methods, which is the reason most minetomill strategies focus on optimizing blast design to produce a desired particle size distribution (Shields and Silva 2022)The primary Integrating Underground Blast Fragmentation Modeling for 2023年5月12日 In position a (Fig 1a) the length l 1 of the lower part of the chamber 1 is minimal, the grinding bodies 2 in it are located at the maximum level h 1Center of masses (CM 1) of grinding bodies (GB) in chamber 1 is located at the minimum distance a 1 from the filling bottom and at the distance b 1 from the crushing cylinder body The length l 2 of the lower part of the Power Calculation of BallTube Mill Drives in the

Design and simulation of gear box for stone crushing ball mill

2022年1月1日 The ball mill is used for the conversion of the raw stone material into the powder form by using steel balls inside The ball mill is a cylindrical form of container that is driven by a toothed circular gear by couple of gears present in the gear box Motor used for the ball mill is taken from the calculations above and from the data sheets To calculate ball mill circulating load, you need to know two important factors: the size distribution of the material going into the circuit and the size distribution of the material coming out of it This information can be obtained through particle size analysis or using data from previous testsload calculation for ball mill circulating – stone cruxder2013年8月28日 SAMPLE CALCULATION: 1 Determine the volume you require: Multiply (LENGTH in FEET) x (WIDTH in FEET) x Marble Crushers, Marble mining, calculation in marble mining Mining Quarry Plant2024年4月27日 This stone calculator is a calculator that can simply help you find the volume of stones you need for your project based on the stone's dimensions If you know the material and the cost per unit mass or unit volume in your region, you can also work out the costs of your stone , using the advanced mode of the calculatorStone Weight Calculator

.jpg)

COSTS AND COST ESTIMATION Chapter NUBE MINERA

2024年8月31日 a 5 day week and 350 for a mine or mill operating continuously 7 days per week with only minor shutdowns or holidays per year 6322 Personnel Requirements Operating costs and capital costs are influenced by the num ber of personnel required to 2024年8月8日 Unlock the secrets to ball mill efficiency with our comprehensive guide on choosing the right grinding media Learn how material composition, size, shape, hardness, and cost impact your milling process and outcomes This makes them especially suitable for heavyduty milling tasks in mining and cement production, where robust grinding media Ball Mill Success: A StepbyStep Guide to Choosing the Construction Aggregate Calculator Enter the width, length, thickness, and product density and hit the “Calculate” button to calculate your estimate If you do not know the product density, use the optional density estimator* or contact a local sales representative Vulcan Materials Company Corporate Office 1200 Urban Center Drive Construction Aggregates Vulcan Materials4 天之前 That’s why we built our online material calculator 😎 In this article, we will show you just how easy it is to use In addition, we will walk you through a few full examples with the mathematical formulae the calculator uses Our material MATERIAL CALCULATOR [How Much Material do

.jpg)

Stirred media mills in the mining industry: Material

2020年5月1日 Stirred media mills are used by the mining industry for ultrafine grinding to enhance liberation, and to decrease particle sizes of industrial minerals to tailor functional properties%PDF16 %âãÏÓ 4215 0 obj > endobj 4235 0 obj >/Encrypt 4216 0 R/Filter/FlateDecode/ID[87C03FABF6FB2246BC4F9AB649B4B217>]/Index[4215 26]/Info 4214 0 R/Length 101 AusIMM – Leading the way for people in resources2016年7月20日 %PDF17 %âãÏÓ 13659 0 obj > endobj 13685 0 obj >/Filter/FlateDecode/ID[4C223A253B0EB081E1EBE09ADB>50343FACDE5D76506BFDB5>]/Index[13659 40]/Info SyKlone International2021年8月9日 metallic commodities, particularly construction material A similar pattern is followed in India with specific rate royalties being applied to nonmetallic, bulk minerals such as limestone and limeshell The complete list of mineral royalty rates of the top 19 mining jurisdictions can be referred to in AnnexA 4 Choice of royalty ratesMinerals royalty rates in India: Comparison with other

Reduction of Fragment Size from Mining to Mineral

2022年10月4日 A notable fact is that the energy efficiency of conventional milling is only about 1%, as mentioned in Sect 1 An earlier experimental study indicated that about 80–90% of the energy input of a ball mill was used in heating the material (Schellinger 1951, 1952), and a recent study showed that over 75% of the electrical energy was used to heat the slurry (Bouchard et 2016年3月21日 Mill Water to Ore Ratio Requirements Resistance of Various Materials to Crushing Pulp Calculations W—Tons of solids per 24 hours R—Ratio of weights: solution/solids V—Ratio of volumes: solution/solids L—Specific gravity, solution P—Specific gravity, pulp S—Specific gravity, solids Specific Gravity Details Pulp Details by Common Basic Formulas for Mineral Processing Calculations 2016年2月26日 The hammer mill is the best known and by far the most widely used crushing device employing the impact principle of breaking and grinding stone Thus far we have described machines which do a portion of their work by impact, but the only machine described in which this action plays an important role was the sledging roll type and particularly the Edison roll crusher Hammer Mill Crusher Grinder 911MetallurgistGrinding media influence the energy consumption and efficiency of the grinding process during the calculation of the Bond Work index (BWi), a wellknown method for selecting comminution equipment, evaluating milling efficiency, and calculating required milling power Traditional grinding tests often choose steel balls as the grinding media, but ceramic balls are used widely A New Approach to the Calculation of Bond Work Index with

Stirred media mills in the mining industry: Material

2020年6月1日 In the mining industry, the ideal target particle size for comminution is the liberation size, the size around which the valuable mineral can be effectively separated from the gangue by physical or chemical methods [10] (usually froth flotation), thereby minimising gangue particles in the concentrate and minimising valuable mineral particles lost to the tailings2013年8月3日 In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do Often, the ball used in ball mills is oversize “just in case” Well, this safety factor can cost you much in recovery and/or mill liner Calculate and Select Ball Mill Ball Size for Optimum GrindingAMIT 129: Lesson 7 Mine Explosives and Blasting; AMIT 129: Lesson 8 Mine Maps, Emergency Evacuation, Barricading; AMIT 129: Lesson 9 Mine Fires and Fire Fighting; AMIT 129: Lesson 10 Mine Ground Control; AMIT 129: Lesson AMIT 135: Lesson 5 Crushing – Mining Mill 2024年7月14日 The word "tonnage" itself can mean a lot of things We can use tonnage to describe the sizing of an HVAC system or how much a ship weighs Basically, tonnage is the weight in tonnes (or tons for short) of massive volume objects, such as the contents of a cargo ship or earthworks like rocks and gravels This calculator focuses on the latter, particularly the Tonnage Calculator

MINERAL MINING TECHNOLOGY Limestone Quarry

2017年8月26日 The study also helps to calculate the desire quality of the limestone that will be brought from other sources throughout the life of the quarry Keywords: LIMESTONE QUARRY PRODUCTION PLANNING FOR CONSISTENT SUPPLY OF RAW MATERIALS 983 JOURNAL OF MINING SCIENCE Vol 51 No 5 2015 T 1 t1 1 Max if 60 and 90 where 0 otherwise N it i i2023年4月23日 global energy in the copper mining industry and it cou ld reach 642% by 2025 [4] Media loading is the amount of grinding material fed into the mill In an experiment to determine the effect (PDF) Grinding Media in Ball MillsA Review ResearchGate2016年6月6日 SAG Mill Circuit Sampling Many mills have been built based on data from inadequate sampling or from insufficient tests With the cost of many mills exceeding several hundred million dollars, it is mandatory that geologists, mining engineers and metallurgists work together to prepare representative samples for testingSAG Mill Grinding Circuit Design 911Metallurgist2019年12月23日 The major factors considered for the material selection are the mechanical properties, wear of materials, environmental properties, fabrication properties and costDEVELOPMENT OF A HORIZONTAL SHAFT HAMMER MILL CHAPTER

Mill, material, and process parameters ScienceDirect

2019年8月1日 The wet grinding processes were carried out in circuit operation mode The following mill geometries were used: an annular gap mill with pins (Advantis V 15, Bühler AG), a disc mill (PML1, Bühler AG), a pin mill (Labstar LS 1, Netzsch Feinmahltechnik), and an accelerator mill (NPM, WAB AG) These geometries are depicted in detail elsewhere [47]4 天之前 As a shortcut, try our cubic yardage calculator to conveniently calculate your volume Step Two: Calculate Gravel Weight in Tons Armed with the volume of material needed in cubic yards, the weight of material in tons can be found by multiplying the volume by the material density Most gravel weighs 14 to 17 tons per cubic yardGravel Calculator Estimate Yards and Tons Inch CalculatorComprehending milling calculations is crucial for optimizing ball mills’ performance in mining operations Factors such as mill size, rotational speed, and power requirements all play significant roles in achieving efficient grinding processes that yield desirable outcomes Common Mistakes in Ball Mill Calculations and How to Avoid Them ball mill calculation for mining machinery – stone cruxder2015年6月19日 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill Ball Mill Design/Power Calculation

.jpg)

Integrating Underground Blast Fragmentation Modeling for

2024年9月1日 21 Role of Blast Design in Sustainable Mining and Mineral Processing Utilizing blasting for rock fragmentation offers distinct cost advantages over employing crushing and grinding methods, which is the reason most minetomill strategies focus on optimizing blast design to produce a desired particle size distribution (Shields and Silva 2022)The primary 2023年5月12日 In position a (Fig 1a) the length l 1 of the lower part of the chamber 1 is minimal, the grinding bodies 2 in it are located at the maximum level h 1Center of masses (CM 1) of grinding bodies (GB) in chamber 1 is located at the minimum distance a 1 from the filling bottom and at the distance b 1 from the crushing cylinder body The length l 2 of the lower part of the Power Calculation of BallTube Mill Drives in the 2022年1月1日 The ball mill is used for the conversion of the raw stone material into the powder form by using steel balls inside The ball mill is a cylindrical form of container that is driven by a toothed circular gear by couple of gears present in the gear box Motor used for the ball mill is taken from the calculations above and from the data sheets Design and simulation of gear box for stone crushing ball millTo calculate ball mill circulating load, you need to know two important factors: the size distribution of the material going into the circuit and the size distribution of the material coming out of it This information can be obtained through particle size analysis or using data from previous testsload calculation for ball mill circulating – stone cruxder

calculation in marble mining Mining Quarry Plant

2013年8月28日 SAMPLE CALCULATION: 1 Determine the volume you require: Multiply (LENGTH in FEET) x (WIDTH in FEET) x Marble Crushers, Marble mining, 2024年4月27日 This stone calculator is a calculator that can simply help you find the volume of stones you need for your project based on the stone's dimensions If you know the material and the cost per unit mass or unit volume in your region, you can also work out the costs of your stone , using the advanced mode of the calculatorStone Weight Calculator2024年8月31日 a 5 day week and 350 for a mine or mill operating continuously 7 days per week with only minor shutdowns or holidays per year 6322 Personnel Requirements Operating costs and capital costs are influenced by the num ber of personnel required to COSTS AND COST ESTIMATION Chapter NUBE MINERA2024年8月8日 Unlock the secrets to ball mill efficiency with our comprehensive guide on choosing the right grinding media Learn how material composition, size, shape, hardness, and cost impact your milling process and outcomes This makes them especially suitable for heavyduty milling tasks in mining and cement production, where robust grinding media Ball Mill Success: A StepbyStep Guide to Choosing the