Coal Grinding Mills Russia

.jpg)

Determining Optimum Productivity of a Ball Drum Mill When

2021年2月8日 Ball drum mills (BDM) are one of the main types of coalgrinding equipment in Russia A significant drawback of BDM is high power consumption (a significant part of the 2017年8月12日 The speciallydeveloped hydraulic roller relief system enables grinding of different fuels (both hard and soft) and improves the machine control response Individual LOESCHEMILLS2023年8月1日 In 2014, the volumes of Russian coal exports for the first time exceeded domestic coal consumption, making Russia a major global coal industry player With incomes over USD The Russian coal industry in an uncertain world: Finally 2023年10月9日 In 2021, coal production in Russia amounted to 438 million tons, and the share of ten leading coal mining companies accounted for more than 70% of total coal productionTop10 Russian coal mining companies

About Us Loesche

4 天之前 Thanks to its grinding plants with throughputs of 2 to 1000 t/h for the cement industry and selfinert, central coalgrinding plants for hard and brown coal power stations, Loesche is the global market leader for vertical mills and 2024年9月28日 There are many Russian miners will cooperation with our Chinese brand powder grinding mills every year As the picture shows, there is our Raymond mill is ready to ship to Clirik YGM Raymond Roller Mill in Russia2022年8月19日 To examine the extent to which Russia’s coal companies address climate change risks and vulnerabilities, we undertook a narrative analysis of corporate reporting To Russian coal in a changing climate: risks and opportunities 2024年6月18日 The following are the five largest coal mines by production in Russia in 2023, according to GlobalData’s mining database, which tracks more than 33,000 mines and The five largest coal mines in Russia Mining Technology

.jpg)

The Russian coal sector in a low Climate Strategies

2021年11月29日 apparent in the Russian coal sector External pressures are increasing as the lowcarbon policies of importing countries result in declining demand for Russian coal The 2024年1月11日 1 To pulverize crushed coals in a ball mill, you start by feeding the mill with crushed coal Then the grinding media crushes and grinds the coal in the rotating chamber 2 Airflow carries the pulverized coal out of the ball mill 3 How to Process Coal into Pulverized Coal in 5 2016年12月19日 GPSE supplies standalone MPS coal grinding mills as well as complete coal grindingdrying systems Both mill and grinding system can be operated under pressure or suction as well as under air or inert gas atmosphere System configurations cover grinding plants with temporary storage of the pulverised coal in silos (cement works, blastfurnaces inCOAL GRINDING IMPS: more than meets the eye Gebr2024年9月28日 In coal combustion, the efficiency and safety of the process are paramount Indirect firing coal grinding systems play a critical role in optimizing these aspects, especially in industrial applications such as power plants and cement manufacturing This article explores the components, advantages, and operational considerations of indirect firing cIndirect Firing Coal Grinding Systems: Enhancing Efficiency

Improving the efficiency of the coal grinding process in ball

2022年2月24日 Improving the efficiency of the coal grinding process in ball drum mills at thermal power plants February 2022; EasternEuropean Journal of Enterprise Technologies 1(1 (115)):93105;2020年8月12日 Vertical Coal Mill (VCM) is equipment for grinding and pulverizing coal into micron size Rotary kilns then use the powders as fuel burners The VCM has a housing section equipped with a lining An investigation of performance characteristics and 2021年2月8日 Abstract Ball drum mills (BDM) are one of the main types of coalgrinding equipment in Russia A significant drawback of BDM is high power consumption (a significant part of the TPP’s own needs) With a huge scale of production, reducing these costs even by a few percent gives a significant economic effect The problem of minimizing the specific energy Determining Optimum Productivity of a Ball Drum Mill When Sharpstone Grinder Mill; Jefferies Coal Crusher; Concrete Grinding Machines; Ligne Production Sable; Coal Crusher Stone Crushing Plant Project; Micro Powder Grinder Manufacturers; Mining equipment manufacture in Russia has many crushers and grinding mills parters in Russia, liming supplies good quality mining crushers and grinding mills forAbout Russian Crushers Crusher Mills, Cone Crusher, Jaw

.jpg)

Ensuring Safety in Coal Mills Coal Mill Safety, Explosion and

2024年9月28日 Coal mills, essential components in power generation and various industrial processes, pose significant safety risks if not properly managed These mills, used to grind coal into a fine powder for combustion, present potential hazards such as fire, explosion, and mechanical failures This article outlines best practices and precautions to ensure thName:Coal Preparation Vertical Coal Mill For Coal Chemical Industry Type:Coal Grinding Capacity:10~90 T/h Motor Power:1101120kwQuality Vertical Coal Mill, Limestone Vertical Mill factory, 2021年4月27日 Coal Mill Temperatures Coal mill hot air inlet temperatures never be more than 600should F and the outlet temperature should not exceed 200°F on Raymond coal mills If the flow of raw coal to the coal mill is interrupted for any reason (for example: plugging, failure of the coal feeder, etc), the outlet temperature of the coal mill can COAL GRINDING SYSTEMS SAFETY CONSIDERATIONS4 天之前 Nowadays, Loesche vertical mills form the core of many plants used to drygrind coal, cement raw materials, granulated slag, industrial minerals and ores Thanks to its grinding plants with throughputs of 2 to 1000 t/h for the About Us Loesche

Reliable Coal Pulverizers and Mills » Babcock

BW's coal pulverizers and mills set the standard for quality, durability, and superior performance, capable of accommodating a wide variety of coals and load swings to the latest BW Roll Wheel™ pulverizer capable of grinding up to 2023年8月28日 Its coal mills are designed to minimize emissions and meet strict environmental regulations Efficient grinding processes reduce coal consumption and prevent coal wastage, contributing to a more sustainable power generation process Market Impact: Bellian Machinery's coal mills have made a significant impact in the thermal power industryCoal Mill in Thermal Power Plant: Enhancing Efficiency and DOI: 101016/JPOWTEC201402044 Corpus ID: ; Exploring ball size distribution in coal grinding mills @article{Bwalya2014ExploringBS, title={Exploring ball size distribution in coal grinding mills}, author={Murray Mulenga Bwalya and Michael H Moys and G J Finnie and François K Mulenga}, journal={Powder Technology}, year={2014}, volume={257}, pages={68 Exploring ball size distribution in coal grinding mills2024年9月28日 You will be surprised about what has gone wrong with fire and explosion protection of your system(s) Be sure about that! Evaluation of a coal grinding system’s fire and explosion protection, including the raw coal storage and the fine coal silo storage normally can be done in one day, mostly without having to stop coal grindingFire and explosion protection of coal grinding systems

.jpg)

Exploring ball size distribution in coal grinding mills

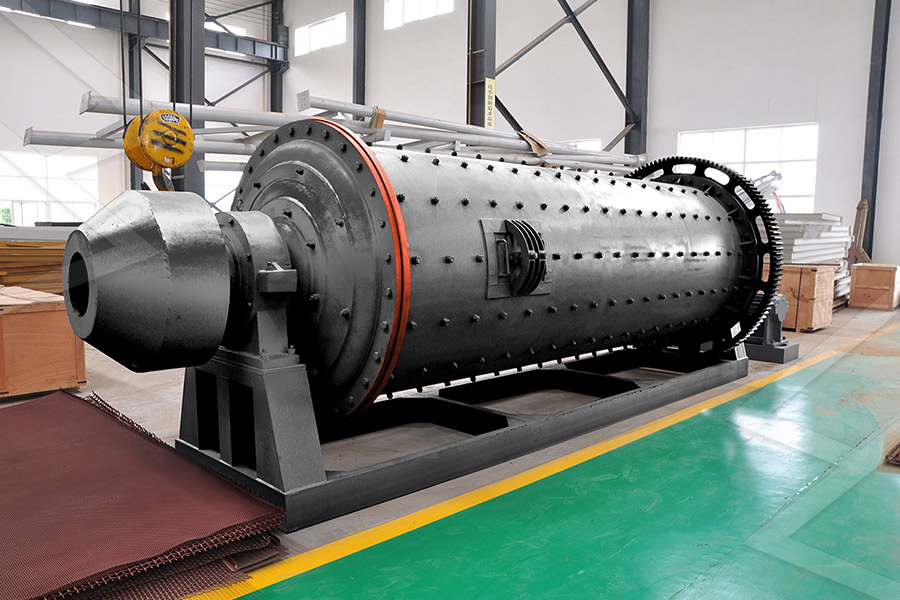

2014年5月1日 Tube mills use steel balls as grinding media Due to wear in the abrasive environment it is necessary to charge new balls periodically to maintain a steady balanced ball charge in the mill Grinding kinetics of coal in wet ballmilling using the Taguchi method 2022, International Journal of Coal Preparation and Utilization Particle size 2011年10月21日 Description of the inerting process in coalgrinding systems Inerting systems avoid dust explosions and smouldering fires in silos, coal mills and filter equipment by creating an inert atmosphere In the case of abnormal levels of carbon monoxide (CO), oxygen or heat, the inerting process is initiated automatically through a processcontrol Emergency inerting systems for coalgrinding applications2018年10月23日 Coal by Microbubble Flotation," Virginia Polytechnic Institute and State University, Blacksburg, VA, 17 pp Dry grinding studies of coal in a rod mill SDasand J S Murty % Retained 20 100 210 220 180 60 210 It AbstractIn this paper, a report is given ofstudies ot!dertaken in a laboratory rod mill to obtain theDry grinding studies of coal in a rod mill Springer2024年7月16日 a standalone coal mill grinding system When a complete clinker line is purchased the attention paid to the details of the coal grinding system with regards to explosion and fire protection will usually be limited to a list of standards, codes and rules to be complied with by the supplier However, when new coalSafety considerations when purchasing a standalone

.jpg)

Coal Grinding Cement Plant Optimization

Elements of Coal Grinding System: Mill Feeding: Consists of following activities Coal Crusher: Generally, require when ball mill is used for grinding and raw coal size is on higher side(>25mm) Conveying to Hoppers: Covered belt conveyors, horizontal or inclined are most suitable and commonly used for conveyingCoal, lignite or petcoke are ground in the Pfeiffer vertical mill by using hot gases from a hot gas generator The grinding plant can be inerted The raw coal is dried while being ground in the mill even if feed moisture exceeds 25% The feed Coal mills for all requirements Gebr PfeifferPulverizers Coal Grinding Roller Mills William’s Vertical Roller Mill Pulverizers utilize centrifugal force to grind coal particles while maintaining low operating costs This product features easily replaceable wear parts, automated process Coal Crushers Coal Pulverizers Mills2020年8月12日 Obtained results indicate that grinding pressure, primary air (PA) temperature and mill motor current have a tendency to rise by increasing coal feeding mass flow rates for all used coal Ultimately, the energetic efficiency of coal mill has been investigated and performance value has been found to be a maximum value of 962% KEYWORDS An investigation of performance characteristics and

.jpg)

coal grinding machine CHAENG

2024年10月18日 Process introduction Vertical coal mill, also known as vertical roller coal mill or vertical coal grinding mill, is a mechanical equipment for crushing and grinding coal into coal powerMainly used for grinding raw coal, bituminous coal, and other fuels into coal powder, which is supplied to rotary kiln and other kilns in the cement plant and thermal power plant2016年3月1日 Similarly, in October 2014, Misr Beni Suef Cement announced plans to build a US$279m coal mill by the end of 2015 Next, in November 2014, Titan Cement ordered a Gebr Pfeiffer SE type MPS 2800 BK vertical roller mill for coal Coal for cement: Present and future trends Global CementMBE’s PALLA® mill has proved to be very efficient grinding equipment with applicability in more than 160 different types of materials and obtaining the required product size and distribution PALLA® is a vibratory grinding mill which produces the required grain sizes in a simple continuous grinding process without any requirement of PALLA MILL MBE2017年2月20日 Grinding Mill Specifications Data According to formula 423/√d, where d is equal to internal shell diameter within new liners In this case the thickness used was 60 mm for small mill sizes up to and including 2940 and 80 mm for larger millsGrinding Mill Design Ball Mill Manufacturer

Grinding ABB

More powerful and larger mills, higher ball charges and demanding ambient conditions call for a strong partner for grinding solutions We help you meet these challenges with our drive systems that come with a long track record in improving performance and extending technical frontiers of all three mineral grinding applications: Gearless mills, ringgeared mills and high pressure DOI: 101016/jengfailanal2022 Corpus ID: ; The Wear Mechanism of Mill Beaters for Coal Grinding Madeup From High Manganese Cast Steel @article{Bembenek2022TheWM, title={The Wear Mechanism of Mill Beaters for Coal Grinding Madeup From High Manganese Cast Steel}, author={Michael E Bembenek and Janusz The Wear Mechanism of Mill Beaters for Coal Grinding Made Name:Coal Preparation Vertical Coal Mill For Coal Chemical Industry Type:Coal Grinding Capacity:10~90 T/h Motor Power:1101120kwQuality Vertical Coal Mill, Limestone Vertical Mill factory, 2024年1月11日 1 To pulverize crushed coals in a ball mill, you start by feeding the mill with crushed coal Then the grinding media crushes and grinds the coal in the rotating chamber 2 Airflow carries the pulverized coal out of the ball mill 3 How to Process Coal into Pulverized Coal in 5

.jpg)

COAL GRINDING IMPS: more than meets the eye Gebr

2016年12月19日 GPSE supplies standalone MPS coal grinding mills as well as complete coal grindingdrying systems Both mill and grinding system can be operated under pressure or suction as well as under air or inert gas atmosphere System configurations cover grinding plants with temporary storage of the pulverised coal in silos (cement works, blastfurnaces in2024年9月28日 In coal combustion, the efficiency and safety of the process are paramount Indirect firing coal grinding systems play a critical role in optimizing these aspects, especially in industrial applications such as power plants and cement manufacturing This article explores the components, advantages, and operational considerations of indirect firing cIndirect Firing Coal Grinding Systems: Enhancing Efficiency 2022年2月24日 Improving the efficiency of the coal grinding process in ball drum mills at thermal power plants February 2022; EasternEuropean Journal of Enterprise Technologies 1(1 (115)):93105;Improving the efficiency of the coal grinding process in ball 2020年8月12日 Vertical Coal Mill (VCM) is equipment for grinding and pulverizing coal into micron size Rotary kilns then use the powders as fuel burners The VCM has a housing section equipped with a lining An investigation of performance characteristics and

Determining Optimum Productivity of a Ball Drum Mill When

2021年2月8日 Abstract Ball drum mills (BDM) are one of the main types of coalgrinding equipment in Russia A significant drawback of BDM is high power consumption (a significant part of the TPP’s own needs) With a huge scale of production, reducing these costs even by a few percent gives a significant economic effect The problem of minimizing the specific energy Sharpstone Grinder Mill; Jefferies Coal Crusher; Concrete Grinding Machines; Ligne Production Sable; Coal Crusher Stone Crushing Plant Project; Micro Powder Grinder Manufacturers; Mining equipment manufacture in Russia has many crushers and grinding mills parters in Russia, liming supplies good quality mining crushers and grinding mills forAbout Russian Crushers Crusher Mills, Cone Crusher, Jaw 2024年9月28日 Coal mills, essential components in power generation and various industrial processes, pose significant safety risks if not properly managed These mills, used to grind coal into a fine powder for combustion, present potential hazards such as fire, explosion, and mechanical failures This article outlines best practices and precautions to ensure thEnsuring Safety in Coal Mills Coal Mill Safety, Explosion and Name:Coal Preparation Vertical Coal Mill For Coal Chemical Industry Type:Coal Grinding Capacity:10~90 T/h Motor Power:1101120kwQuality Vertical Coal Mill, Limestone Vertical Mill factory,

COAL GRINDING SYSTEMS SAFETY CONSIDERATIONS

2021年4月27日 Coal Mill Temperatures Coal mill hot air inlet temperatures never be more than 600should F and the outlet temperature should not exceed 200°F on Raymond coal mills If the flow of raw coal to the coal mill is interrupted for any reason (for example: plugging, failure of the coal feeder, etc), the outlet temperature of the coal mill can